Sucro Limited's New Cane Sugar Refinery in Greater Chicago Area Promises New Jobs and Economic Boost

Sucro Limited announced plans to construct a new cane sugar refinery in the Greater Chicago Area to address the growing and underserved U.S. sugar market. Once complete, the new refinery will have a similar scale to the Company's Lackawanna facility in Western New York. The new refinery will have significant value-added specialty sugar capabilities, including large grain crystals used in specialty foods and confectionery, an integrated brown sugar line, specialty liquid production and organic sugar refining capabilities. Start-up and initial production are expected in 2026.

The Chicago refinery will leverage Sucro's existing property and sugar processing infrastructure at University Park, Illinois. The location represents the most inland cane sugar refinery in the U.S. with the capability to serve food processors and manufacturers in the Midwest with a more efficient supply of refined cane sugar and specialty sugars. We expect to fund the equity portion of the facility's construction costs using internally generated cashflows.

"The U.S. sugar market is chronically short of supply, and demand is growing. This is particularly true in specialty value-added segments like large-grain crystals. "Our new Chicago refinery will add much-needed domestic refinery capacity to address the demand for refined sugar and reduce the market's reliance on imports. The refinery's primary focus will be higher value specialty sugar products which are in high demand from U.S. food processors and manufacturers," said Jonathan Taylor, CEO and Founder of Sucro. "The Chicago refinery will represent Sucro's third new facility in the past five years. Once the new Chicago refinery and the recently announced new refinery in Hamilton are complete, we believe Sucro will be responsible for adding more new capacity to the North American market than all other sugar refiners combined. Sucro is also unique in the industry as the only sugar refiner in North America to widely make available less processed, higher color refined granular sugar. This is the highest growth, most sought-after feature by our multinational customers looking for innovation and flexibility."

"I'm happy that Sucro will continue to invest in University Park, proving that the Chicago South Suburbs remain one of the best places to live, work, and raise a family," said Congresswoman Robin Kelly. "This investment will create new jobs and continue to grow an economy that works for everyone."

"This project reinforces the successful partnership the Village has developed with Sucro over the past three years," expressed Mayor Joseph E. Roudez, III. "We are excited for the positive economic impact this will have through improved infrastructure, job creation, and taxation, and we are grateful they chose to further invest in the second largest Industrial Corridor in the State of Illinois."

Mr. Taylor continued, "The new refinery will be closely integrated with our existing production assets in Western New York and Southern Ontario, leveraging the strengths and operating capabilities of a highly efficient network of facilities. The integrated nature of our production assets is designed to supply competitively priced refined cane sugar for our blue-chip customer base of multi-national food manufacturers in the Midwest."

The Chicago asset will have fully integrated logistics infrastructure, including inbound and outbound rail and on-road transport capabilities. The new refinery is expected to have 75 full-time equivalent manufacturing and administration positions once completed. Sucro is a minority-certified company and through its partner, Amerikoa, supports the Wounded Warrior Project, an organization that sponsors veteran homeless shelters, and hires local veterans.

Write comment (0 Comments)

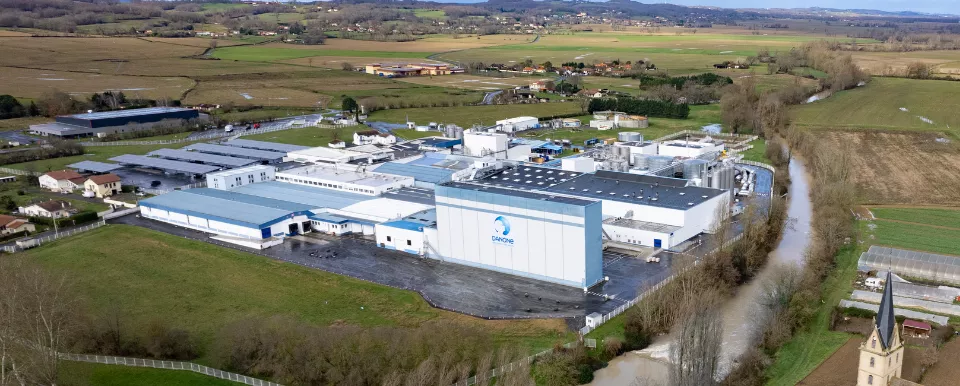

CEO Antoine de Saint-Affrique joined French officials and Danone employees to inaugurate its newly transformed production facility in Villecomtal-sur-Arros in southwestern France. Reflecting Danone’s focus on anticipating consumer needs, the site’s conversion to plant-based makes it a new reference point in Europe for the production of oat-based drinks for the Alpro brand.

Partner of the Paris 2024 Olympic and Paralympic Games, the site will be the starting point for the “Danone Champions Tour”, the largest corporate relay race, with over 1,000 runners on February 19.

Villecomtal is now a center of industrial excellence in the heart of France, serving markets across Europe. Its transformation took nearly two years and called for a capital investment of several million euros. With its cutting-edge technology, the site is now home to Danone France’s only oat-flour-to-oat-juice production facility.

The Villecomtal-sur-Arros plant features two innovative and competitive production lines, one operating at high speed. Beverage output is set to reach over 300,000 liters a day for distribution in France and 26 other European markets. 90% of total production is designated for export, making the site a European showcase for French plant-based products.

The Philippines Lagonglong Port in Misamis is involved in an infrastructure project aligned with the government’s goal of increasing food production. Due for completion in March 2025, Lagonglong Port promises to increase trade capacity in Mindanao, enhance logistical capability in the region, and create new jobs.

Agriculture Secretary Francisco P. Tiu Laurel, Jr. said, “Lagonglong Port dovetails with the Department of Agriculture’s push to boost agricultural production, ensure accessibility to affordable food, and achieve food security for our countrymen,” Secretary Tiu Laurel said during groundbreaking rites for the project.

The project is a private commercial port development of Amadi MGT Terminals Inc. that will cost P4 billion to complete. Amadi will spend P1.4 billion for the first phase which will have an annual throughput capacity of 3.3 million metric tons of bulk cargo. The port will also have storage facilities and modern equipment to handle international and domestic cargo, including perishable goods. Aboitiz Construction is building the multi grains terminal for Amadi.

The groundbreaking was graced by, among others, Senate President Juan Miguel Zubiri, Misamis Oriental Gov. Peter Unabia, Congressman Christian Unabia, Agriculture Undersecretary Roger Navarro and Lagonglong Mayor Jay Albert Puertas.

“We should build more ports like this. This is critical to the modernization of our country. This port, once finished, I believe will reduce feed costs by at least 2.5%, or as much as 5%. It will reduce cost of fertilizers also by 5%, maybe, or as much as 10%, depending on the price,” said Secretary Tiu Laurel.

He added that the port project will increase efficiency of transporting vital goods and provide storage facilities that will help maintain the quality of agricultural products and raw materials once finished.

The agriculture chief said that once completed, the Lagonglong Port should spur the development of factories, processing plants and other value-adding facilities. “I’ve seen that happen, and I’ve done it. In Papua New Guinea, Indonesia, and other areas in the Western Pacific where we built ports,” he added.

Write comment (0 Comments)

Foodics is a company that specialises in restaurant management solutions. They plan to double their business in the Egyptian market this year, aiming to reach over 6,000 restaurants locally by the end of 2024. This is in comparison to the current 3,000. Omar Knio, the Sr. Director of Corporate Communications at Foodics mentioned that the company wants to expand its operations in the Egyptian market, as it has many opportunities to offer. In the coming period, expanding in Egypt will be their focus.

Knio, who spoke on the sidelines of the Forbes Middle East Summit, said that Egypt is a gateway for the company to expand its operations in the promising African market. The company currently provides some services to restaurants in Africa through its operations in Egypt. Foodics intends to establish its presence in Africa soon as part of its ongoing plan, especially due to the significant economic diversity in the region. Expansion in Africa has become a priority for the company.

Knio highlighted that the company mainly targets cooperation and service provision for the upper segment of restaurants, which holds the largest market share in Egypt. He confirmed that Foodics plans to increase its market share in the Egyptian market.

Write comment (0 Comments)

Coca-Cola has launched five new autonomous forklifts (AGVs) at its regional beverage concentrate plant in Singapore, in partnership with XSQUARE Technologies (XSQUARE), Asia Pacific's leading intelligent warehouse automation solutions provider.

Coca-Cola Singapore embarked on this journey as part of its digital transformation strategy. The company supports one of the fastest growing regions in the world, and by embracing Industrial 4.0 capabilities into its plant, it will be able to build supply chain resilience into its system and increase plant capacity in anticipation of future growth opportunities.

XSQUARE's Springer AGVs have been integrated into the plant's shop floor and automated warehouse to transport finished goods within the premises. In addition, the autonomous forklifts have been incorporated with Coca-Cola's existing sub-systems and are able to operate in hybrid working environments. This is enabled by XSQUARE's Xymphony software, which allows for seamless data interoperability and increases operational efficiency.

"Coca-Cola is proud to launch our new AGVs with XSQUARE, leveraging their deep expertise in warehouse optimization and cutting-edge technologies. This marks a new milestone in our Industry 4.0 transformation journey."

"Through our partnership with XSQUARE and ongoing efforts to fully automate our plant in Singapore, we hope to continuously improve our processes, create higher value-added jobs for our workforce, and contribute to Singapore's vibrant ecosystem for advanced manufacturing," said Gerardo Artavia, Plant General Manager, Coca-Cola Singapore.

"As consumer expectations in the region rapidly evolve, it's crucial for warehouses to step up their capabilities. In this dynamic landscape, companies like Coca-Cola recognise the transformative power of intelligent warehousing solutions. We are thrilled to collaborate with them, providing our advanced AGV systems that are tailored for maximum safety, precision, and speed in navigation and storage. Our technology is not just about automation; it's about enhancing human efforts and ensuring efficiency in every aspect," said Jens Bohnwagner, CEO of XSQUARE. "This collaboration with Coca-Cola signifies a crucial juncture in our endeavours to revolutionise warehouses across APAC as we seek to establish new benchmarks in warehousing technology and operations."

The implementation of XSQUARE's intelligent warehouse solutions has already resulted in remarkable improvements in terms of efficiency, safety and orchestration, and there are plans to build upon that success in Coca-Cola's expansion building in Singapore. The company has also recommended XSQUARE to other sister plants, indicating a positive outlook for future joint projects and partnerships.

Write comment (0 Comments)